.

Home >

Products

Home >

Products

Products

OMC Catalog

A vast range of products and technologies that many attempted imitating: the ability to be partners of our customers and not only simple suppliers is what makes the difference.

Contact Us

OMC Catalog

A vast range of products and technologies that many attempted imitating: the ability to be partners of our customers and not only simple suppliers is what makes the difference.

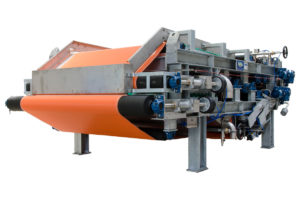

Filtration |

Softening |

Ultrafiltration |

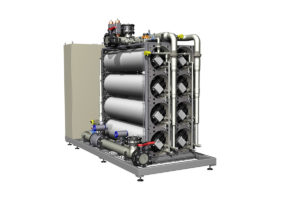

Reverse Osmosis |

Ion Exchange |

Electro Deionization |

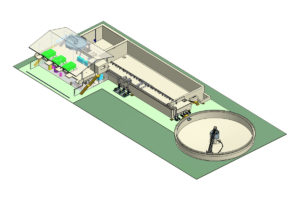

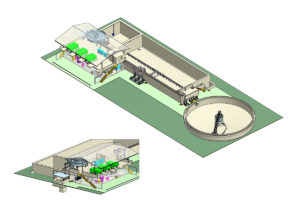

Deltafloat |

Sedideltafloat |

Tigerfloat |

ASR |

New air dissolving system for DAF units. |

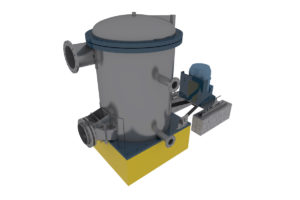

Omegafilter |

Gammafilter |

Microfilter |

Sigmafilter |

Densidisc |

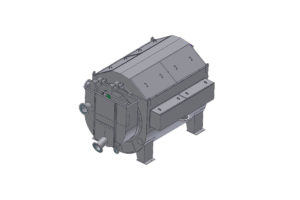

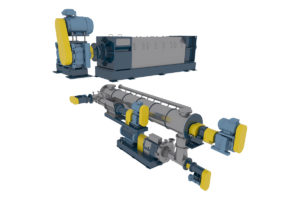

HC – High Density Pulper |

DS – Dumping Screen |

HDC – High Density Cleaner |

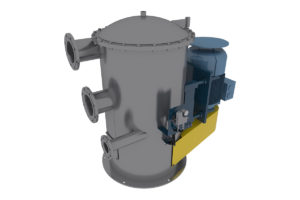

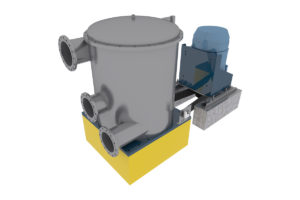

MC – Medium Consistency Screen |

FDC – Flotation Deinking Cell |

LDC – Low Density Cleaners |

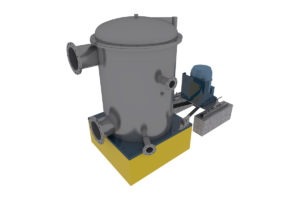

LC – Low Consistency Screen |

WU – Washer Unit |

DUP – Pressurized Disperging Unit Plant |

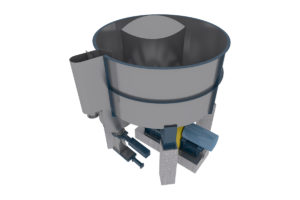

LCC – Low Density Continuous Pulper |

DSC – Dumping Screen Continuous |

RD – Reject Drum |

RG – TC – Ragger – Tail Cutter |

CTP – Coarse Screening |

FF – Fibre Fractionator |

LCB – Low Density Batch Pulper |

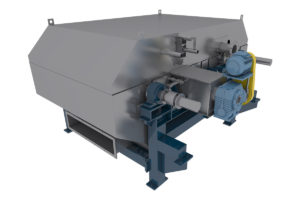

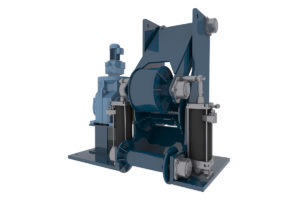

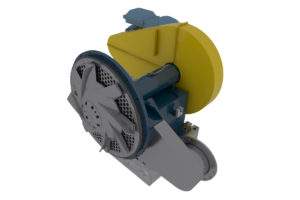

DEF – Deflaker |

DDR – Double Disc Refiner |

AS – Approach Flow Screen |

UBP – Under Machine Broke Pulper |

AFS – Agitators |

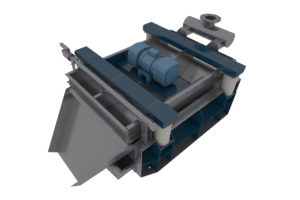

VSL – VSH – Vibrating Screen |